Omega is a leader in Heat Transfer Technology.

Omega Thermo Products is all about Laser Plates; they make tank walls, bottoms, cooling panels and complete heat exchangers consisting of Laser Plates. With the advantages of their product, they always find a solution to heat or cool your product.

Having manufacturing facilities strategically placed around the globe, their products can be seen throughout the world in virtually every industry including Food & Beverage, Chemical, Pharmaceutical, and HVACR.

As the inventors of laser-welding machines for the production of Laser Plates, Omega is a pioneer in the industry. Their team of technical engineers is driven, innovative, and always open to new ideas. They are happy to come up with a solution for your problem and run a heat transfer calculation for you.

Omega’s Research & Design departments are continually working to develop their laser welding machines for more efficient production.

In the food, chemical and pharmaceutical industry, needs are increasingly more stringent and the demands on their plates and heat exchangers has also become stricter. They stay on top of market changes by continuing to develop their laser welding machines.

Laser Welded Tank Shell

Laser Plate on Tank Walls

|

In many industries Omega Laser Plates are used to heat or cool tanks. Laser Plates have a higher rate of heat transfer and often have an overall lower cost because no post-processing needs to take place. In addition, thinner materials can be used with Laser Plates than with half-pipe tank walls or double-sided construction.

The sidewall and heads of a tank can be heated or cooled using Laser Plates and will be ordered and delivered with the heat transfer surface already welded to the tank shell or head. Your tank plates are welded by their laser welding machines, after which you can roll or form them into the desired shape. After fabricating the tank, the Laser Plates are inflated to form a vessel that the heat transfer medium will flow through. |

|

Half Pipe/Double-Walled Vessel

Initially tanks that needed heat transfer were made with a double wall design. From there things evolved and half pipe was welded on to create a more efficient channel for the heat transfer medium to flow through. The technology has evolved again into an even more efficient and cost effective method which is Laser Plates.

Space requirements play an important role in tank construction. Compared to half pipe construction, you can save up to 1/3 of that space with Omega Laser Plates. In addition, it is easier to make an isolation (for example for a manhole) in the jacket of the tank in the desired location.

Click here to Request a Quote.

Flange and Dished Head

Flanged and Dished Heads with Omega Laser Plate

|

Omega Thermo Products is one of the few suppliers that can also supply F&D heads with Laser Plates under ASME, CE-PED, and CRN. Many of the bottoms supplied by Omega are used in the chemical and pharmaceutical industry. Also F&D heads are used for process tanks, with a full vacuum or high pressure prevailing in the tank.

Design

Two flat sheets of stainless steel are welded together and after this process the flat head is sent out for forming. Generally the Laser Plate covers 80% of the heads surface to allow the head to be formed without forming on the laser welded portion. The forming is hydro formed or bump formed depending on the size. The heads are sent to the customer fully formed, trimmed and ready to be installed on the tank. Once the head is installed the jacketing will be inflated hydrostatically.

|

|

Advantages

Using a laser welded head is a cost savings over welding on pre-formed dimple. There is also flexibility in design for isolations of tank connections and openings.

Other Tank Bottoms

Beside Flanged and Dished heads we can also provide cones or reverse dished heads with Laser Plates.

Click here to Request a Quote.

Immersion Heat Exchangers

Immersion Products

|

With Omega’s Immersion Plates it is easy to directly heat or cool a liquid. The sturdy design ensures that the product is easy to clean and maintain. Whether it is for clean water or heavily contaminated liquids, Laser Plates can maintain performance.

Immersion Plates were initially used to heat or cool highly contaminated liquids. Several industries use this efficient method of direct heating and cooling.

How Does an Immersion Plate Work?

Immersion products are individual plates or a bank of several Laser Plates that are immersed in a container with liquid. The medium in the plates heats or cools the liquid in the container, depending on your needs. This can be done in a continuous or a batch process. |

|

Air Agitation

In order to obtain a turbulent flow on the wall of the plate, air agitation is suggested and used in some cases. This ensures a higher rate of heat transfer. An air pump blows air through a perforated pipe system, creating a whirlpool effect. This is especially recommended for cooling in Ice Bank applications.

Advantages

| • | Heating and Cooling a Variety of Liquids, even Liquids with High Viscosities | |

| • | Easy to Maintain Due to Sufficient Space Plate Spacing | |

| • | Compact Design that can be Used for Multiple Applications | |

| • | Can also be Used with Highly Variable Volume Flows |

Click here to Request a Quote.

Clamp-on Heat Exchangers

Tank Heating and Cooling Jacket

|

Heating, cooling, or maintaining temperature of an existing tank is easy with Laser Plates. Using Laser Plates saves the cost of building a new tank, makes the heat exchanger easy to take off and replace and can be easily placed anywhere on the tank.

Omega Thermo Products makes single embossed and double embossed clamp-on plates depending on your needs.

How Does a Clamp-on Work?

Based on your data, they can calculate the required capacity to cool the existing tank or to heat it to the desired temperature.

|

|

Our tank clamp-on jackets are first welded as a flat Laser Plate, after which we roll and inflate them in the desired shape. You will receive the tank heating and cooling jacket completely finished with the right connections and isolations. All you need to do is mount it on your tank.

In most cases, Omega tank clamp-on jackets are double embossed. There are pillows on both sides of the jacket. By using heat transfer mastic, the clamp-on jacket fits up to your tank and the mastic fills in the air gap left by the pillowed shape.

Single Embossed Tank Clamp-on Jacket

Single embossed clamp-ons are used in high temperature applications because a hardening mastic is needed to operate in higher temperatures.

Advantages

| • | Easy to Change | |

| • | The Old Tank does not have to be Replaced | |

| • | No Need for Welding on the Existing Tank | |

| • | Heating or Cooling is Physically Separated from the Tank Containing the Product so there is no Cross Contamination | |

| • | Exact Product Placement for where the Tank needs to be Heated or Cooled | |

| • | The Low Volume of the Clamp-on Plates Allows you to Easily Control the Temperature of the Tank or Reactor |

Click here to Request a Quote.

Ice Machines

Industrial Ice Machine

|

Our Industrial Ice Machines are used in many different industries. If you need large quantities of ice to cool your products, their Ice Machine is a good solution. By using Omega Laser Plates, you will get a machine that is relatively small in size and is easy to maintain. Based on your needs, Omega Thermo Products will run heat transfer calculations to see which capacity of Ice Machine you need. Their Ice Machines are always custom-made and designed to your specification.

How Does an Ice Machine Work?

At the top of the Ice Machine, water is pumped in and falls through small holes then slowly flows down the Omega Laser Plates. The coolant in the Laser Plates cools the water down until it is frozen. When the ice on both sides of the plate is approximately 3/16” to 3/8” thick, then hot gas is injected into the Laser Plates, causing the plates to warm up and release the ice from the plates. The ice falls into a storage tank and breaks into smaller pieces. This ice can be transported by a transport screw to the desired location.

|

|

Advantages

| • | No Moving Parts which means Maintenance is Minimal | |

| • | Low Energy Consumption | |

| • | High Ice Production for such a Small Machine | |

| • | Easy to Keep Clean |

Click here to Request a Quote.

Ice Bank

|

The idea behind the Ice Bank is simple: at off peak electricity hours, such as at night, ice is generated on the plates with our Laser Plate technology. This ice is then used during the day to cool your product. We call this thermal energy storage.

High peak loads in the summer drive the investment expenditure of the electricity production industry. A kW of electricity consumed at night can be produced at a much lower marginal cost. Energy companies pass on these lower costs to the consumer through Real Time Pricing Rates. That is why thermal energy storage by Omega Ice Banks is a good investment.

|

|

How Does an Ice Bank Work?

An ice bank is a package of Laser Plates that is hung in a container with water. At night when the energy is at a lower price, the plates freeze the water in the tank. During the day when the power is more expensive, the cooler is turned off. The ice will melt into ice water. This ice water can be used to indirectly cool your products.

Advantages

| • | Save on Energy Costs | |

| • | No Peak Load | |

| • | Low Maintenance Costs | |

| • | Compact Design that can be Used for Multiple Applications | |

| • | Consistent Capacity Available through Plate Configuration | |

| • | Our Ice Bank Requires a Smaller Footprint Compared to a Pipe System |

Click here to Request a Quote.

Falling Film Water Chillers

|

The Omega Falling Film Chiller is a water cooler based on Laser Plate technology. With the ability to cool water down to 33°F. From a Falling Film Chiller you can cool large amounts of product in a short period of time. This (recirculating) water cooler, which cools the water at a constant temperature, is a suitable solution for the continuous cooling of many products.

Because every cooling requirement is different, their Falling Film Chillers are always custom-made. Together with their engineers, they will calculate the best solution for you.

What is a Falling Film Chiller? |

|

A Falling Film Chiller is a heat exchanger that cools water to your desired temperature. This cold water is used to cool large quantities of product in a short amount of time, for example, to blanch vegetables or to mix with concrete to prevent the concrete from drying too quickly.

You can also choose to recirculate the water and let Omega Laser Plates cool the water down again to the right temperature. With this recirculating Falling Film Chiller your products are continuously cooled to an even temperature.

How Does a Falling Film Chiller Work?

In the upper cabinet there is a water distribution pan with multiple holes on the bottom that the water will exit the pan through and flow over our double embossed Laser Plates hanging underneath. A thin layer of water falls over the plate and is cooled to the desired temperature. The water can be cooled to 33°F with a Falling Film Chiller.

This cooled water falls off the plates into an optional tank and from there can be pumped and distributed to the next process whether that be another heat exchanger, process tank, or food product. The used water can be collected in a reservoir and pumped back to the top of the Falling Film Chiller for the process to start over again.

Advantages

| • | Efficient Cooling to Very Low Temperatures (33°F) without the Risk of Freezing | |

| • | Consistent Temperature of the Chilled Water | |

| • | Custom-made to Your Needs | |

| • | Easy to Maintain Open Construction. Occasional Cleaning with High Pressure | |

| • | Fully Constructed of Stainless Steel | |

| • | Can Cool Slightly Polluted Water (particles smaller than 5/16") |

Click here to Request a Quote.

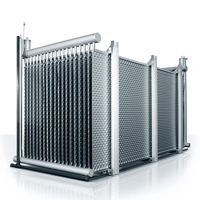

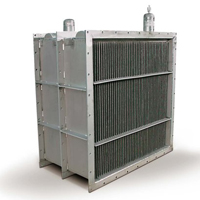

Heat Recovery Bank

|

Heat Recovery Banks capture heat that is exhausted or vented during plant process applications and provides energy savings by using the recovered heat in multiple preheating applications.

Energy Savings

Increased energy costs have made heat recovery a priority in many industries to reduce a large portion of production costs.

Heat recovery banks can be used with wet gas and liquid streams to significantly cut industry fuel bills. While doing this, they are also eliminating troublesome vapor plumes and reducing thermal loads on effluent plants. |

|

Easy installation

The adaptability of Omega's designed heat recovery banks makes it easy to match existing flange patterns and locations, as well as overall size, they can replace any manufacturer’s design. Their design service includes making any changes that would improve a current installation.

Click here to Request a Quote.

Bayonet & Suction Heaters

Bayonet Heaters

|

Bayonet heaters are an energy efficient, water saving alternative to steam sparging for heating process vessels.

Bayonet heaters are installed in the side entry of the tank. A mounting flange, which is provided, is bolted to the side of the tank for ease of insertion and removal. This allows for good natural convection circulation of the fluid being heated. These heaters are ideal for use in recirculating systems and other applications where automatically controlled temperatures are needed. |

|

Suction Heaters

|

The manufacturing process for suction heaters is essentially the same as bayonet heaters with the exception of a four-sided sealed shroud that encloses the plates with an opening on the far end. An outlet flange is then welded to the mounting flange that secures it to the tank. As liquid is pumped out of the tank, it is heated or cooled as it passes over the plates. |

Click here to Request a Quote.