|

Lodige Process Technology is a global leading supplier of mixers, coating systems, granulators, dryers and reactors. Lodige invented Ploughshare® Technology. This technology is effective with the following processes: Mixing (horizontal and vertical); Drying (Contact, Fluid Bed, and Convection); Reacting; Coating; and Granulation (Horizontal and Vertical). |

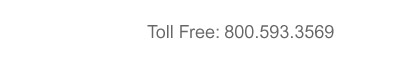

Principle of Operation

The Ploughshare® Shovels are specially arranged and rotate on a horizontal shaft in a horizontal, cylindrical mixing drum. The size, number and positioning, geometric shape and peripheral speed of the mixing elements are designed to cause three-dimensional movement of the components of mix. Complete fluidization and turbulence of the mixed materials is created which eliminates dead spaces or low movement zones in the mixing drum; thus promoting high speed, precise mixing.

The specially shaped shovels lift the product radially from the wall of the drum to prevent particles from becoming compressed between the mixing elements and the drum wall. The mechanically generated fluid bed is therefore ideal for gentle mixing if fragile and heat sensitive components are included in the mix.

Mixing

Lodige Process Technology offers a large variety of horizontal and vertical mixing systems for industrial applications. Customized solutions can involve extremely high mixing quality, short mixing times, reproducibility of batches, gentle product treatment, high availability, low-maintenance mixer concept, easy accessibility of all internal mixer components and multi-stage processes in one machine.

Industries served: Building Materials, Chemical Industry, Cosmetics, Plastics, Metallurgy, Food, Pharmaceuticals, Polysaccharides, Environment

|

|

|

| Ploughshare® Horizontal Mixing | Vertical Mixing Lab Machine |

Click here to Request a Quote.

Drying

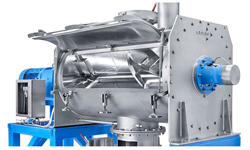

The Lödige dryer was developed from the Lödige Ploughshare® Mixer. It consists of horizontal, cylindrical drum with heating jacket. The product is heated by the jacket and the product moisture is thereby evaporated. A horizontal shaft along the longitudinal axis of the dryer drum is equipped with shovels for mixing the drying product according to the fluid bed principle. This ensures that the product is heated evenly (no local hot spots) and moist material is brought continuously in contact with the heated wall.

The intensity of the product movement increases during the drying process while moisture and therefore viscosity decrease. Use of choppers at the right time produces a bigger heat transfer area and therefore leads to increased drying speed. The dryer is heated by the jacket operated with hot water, steam or thermal oil. Molten salt or an electric heating can also be used to achieve higher temperatures.

Contact drying with the Vacuum Shovel Dryer Druvatherm® provides intense mixing and prevents temperature and moisture gradients within the product. Maximum heat transfer coefficients ensure excellent dryer performance. Other key features include gentle thermal product treatment in vacuum mode, multi-phase processing (mixing, granulation, drying, cooling) and cost-efficient solvent recovery.

Typical applications include: pharmaceuticals, chemical, cosmetics, plastics, polysaccharides and environment.

|

|

|

| Vacuum Shovel Dryer Druvatherm® Lab Machine |

Vacuum Shovel Dryer Druvatherm® |

Click here to Request a Quote.

Reacting

Lodige Druvatherm® reactors are batch, high-speed reactors. The Reactor Druvatherm® is available in lab and standard sizes. The benefits include the rapid uniting of reacting agents, prevention of local over concentrations, no temperature gradients within the reaction field, improved conversion of reacting agents, leading to higher yield with greater purity of the final product and multi-phase process (reaction, heating, drying, granulation, cooling).

|

|

|

| Reactor Druvatherm® Lab Machine | Reactor Druvatherm® |

Click here to Request a Quote.

Coating/Granulation

Coating Solutions

Lodige Process Technology mixing systems are utilized in granulation, agglomeration and coating applications for various industries. The coaters are specifically developed for coating tablets. With their coater range, these machines are the technological market leader in the pharmaceutical industry - providing perfect results in an extremely short time frame.

Granulation

Mixing Granulators (Horizontal and Vertical)

The high-shear mixer is a system for mixing, granulation and sieving of pharmaceutical powders and granulated products. A mixing granulator is suitable for a wide range of cosmetics and food products. Other benefits include: a GMP-compliant design, Modular WIP system for the machine and all additional components, Automatic liquid addition in different versions, New pharmaceutical controls, Temperature control jacket for heating/cooling, Integrated sieve on machine outlet, Vacuum feeder, Customized ATEX concepts.

|

|

|

| Ploughshare® Mixer Horizontal Granulation | Coater System |

Click here to Request a Quote.

| Click below to download the product brochures in PDF Format. |

Lodige System Solutions for Chemical Industry Brochure

Lodige System Solutions for Cosmetic Industry Brochure

Lodige System Solutions for Environmental Technology Brochure

Lodige System Solutions for Food Industry Brochure

Lodige System Solutions for Metallurgical and Mineral Industry Brochure

Lodige System Solutions for Pharmaceutical Industry Brochure

Lodige System Solutions for Plastics & Rubber Processing Industry Solutions Brochure